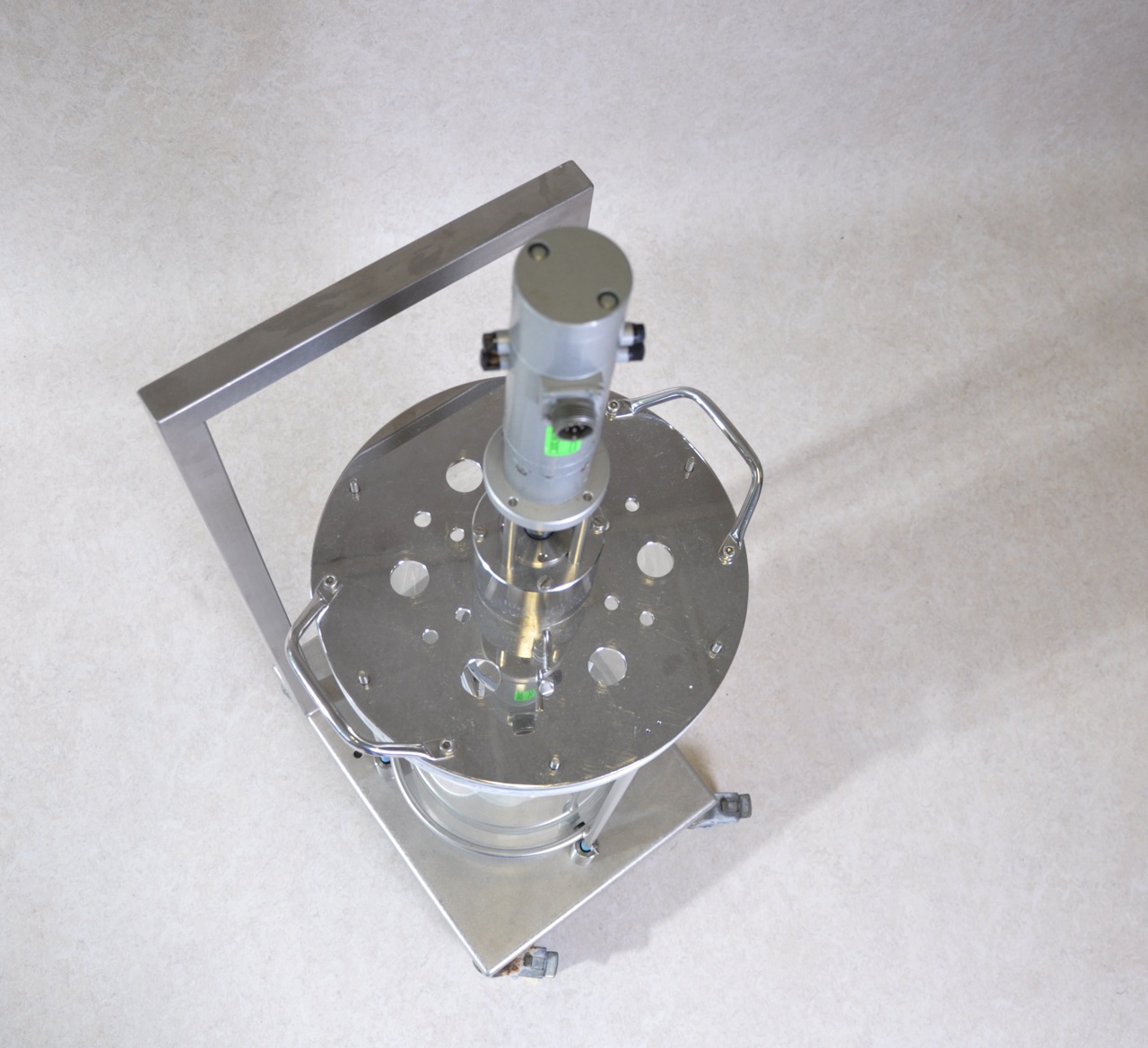

Applikon bioreactor vessel with stirrer, controller and various accessories.Applikon glass autoclavable bioreactor for cell culture applications and glass autoclavable fermentors for microbial culture applications. The systems are built according to the specific demands of a process using an extensive array of standard components. Because of the modularity and flexibility, the user can always adapt the systems to changed process demands. This results in low initial investment and low running costs.

The stirred tank reactor (STR) is the most widely used bioreactor type. Glass autoclavable bioreactors is 20 liter total volume.

This Applikon bioreactor is designed for maximum flexibility in setting up. This means that the systems can be completely customized for the user’s application. When the application changes, the bioreactor set-up can easily be adapted to the changed process demands. Headplates are maof 316L stainless steel and all parts in the bioreactors have an electropolished finish that ensures reliable cleanability of the vessel and components. Glass dished bottom vessels are maof borosilicate glass. Vessels can be used up to 0.5 barg (7.25 psi) of overpressure.

The laboratory scale glass bioreactors and fermentors are designed for research applications such as process optimization, screening studies, product optimization, scale up/scale down studies and for educational programs.